Pipes with Purpose: How to Choose the Right Exhaust

There’s performance, and then there’s Herman.

The exhaust on your Harley isn’t just a piece of metal bolted to the side of your motor—it’s your bike’s voice. It’s the note you hear every time you crack the throttle, the vibration you feel in your chest, and the line your eyes follow from header to tip. The right system can give you more power, sharper throttle response, and a tone that sends shivers down your spine. The wrong one? It’ll rob you of torque, waste fuel, and make tuning a nightmare.

So how do you choose the right one? You start by figuring out what you really want from your exhaust. Some riders are chasing power, looking for that extra punch off the line or top-end pull for highway runs. Others are after sound—whether that’s a deep, rolling rumble or an aggressive, sharp crack that turns heads a block away. Then there’s style. Some want long fishtails stretching past the rear wheel, others want fat touring mufflers that fill the space under the bags, and plenty chase the lean, purposeful look of a 2-into-1. If you don’t decide what matters most to you, you’ll end up shopping blind.

Defining Your Riding Style

Looks Herman Chose Drag Pipes.

Your riding style should shape your exhaust choice just as much as looks or sound. If you’ve got a stripped down bar hopper that spends most of its life under 60 mph, you can get away with short, loud pipes that sacrifice a little low end torque for attitude. Touring rigs that chew up interstate miles need a different approach—heat management, midrange torque, and a tone that won’t drone your ears off at highway speeds are more important than sheer volume. Performance baggers or big inch motors with cams demand systems that move serious air without losing the scavenging needed for clean, strong pulls through the rev range. Match the pipe to the mission, and you’ll avoid most of the headaches riders run into after buying the wrong setup.

Your bike’s setup matters too. A Stage 1 air cleaner with slip ons is a completely different animal from a built 128 inch motor running a big cam. Baggers have different clearance needs than Softails, and carbureted bikes have different tuning realities than EFI models. And here’s a reality check pulled straight from the Mikuni tuning manual—open straight pipes or tiny, see through mufflers might look cool, but they can make proper tuning nearly impossible. You might get it to run at one RPM range, but everywhere else it’ll stumble, run hot, or fall flat.

Performance wise, not all pipes are created equal. A good 2 into 1 will almost always give you better scavenging and stronger midrange pull. True duals have that classic, separated sound and help reduce heat on touring bikes, but you might lose a little low end torque. Drag pipes? Unless you’re building a top end race bike, they’re a bad street choice. They create reversion, which is a fancy way of saying the exhaust gases rush back toward the motor at low RPM, killing throttle response—and over time, long, unsupported drag pipes can sag under their own weight, stressing flanges and mounts.

Header Sizes Through the Eras

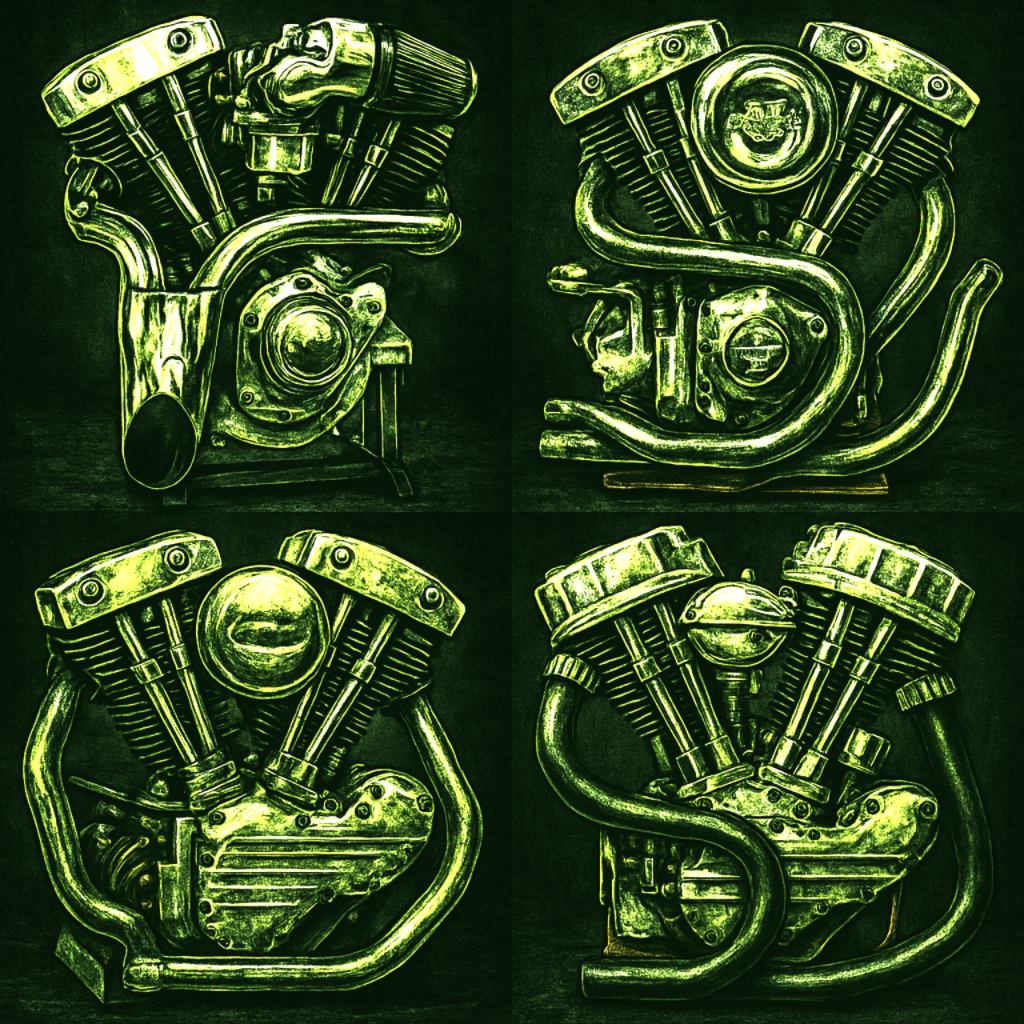

If you’ve ever wondered why some Harley pipes just work while others leave you chasing leaks and flat spots, it often comes down to header size. Harley hasn’t exactly reinvented the wheel over the decades, but small changes through each engine era matter when you’re bolting up pipes.

On the old Panheads (1948–1965), the factory pipes sat right around 1 ¾″ outer diameter. That size kept the exhaust gases moving quick, which gave those motors great bottom end torque and crisp throttle response. Bump the diameter up too much and the exhaust velocity slows down, which robs you of grunt where you need it most.

The Shovelheads (1966–1984) stuck with 1 ¾″ as well. Sure, some drag bikes pushed into the 2″ range, but unless you’re wringing one out at the strip, that bigger pipe usually costs you power in normal riding.

By the time the Evolution Big Twins (1984–1999) rolled in, 1 ¾″ was still the standard. Toward the end of the Evo run, though, you started seeing 1 ⅞″ primaries on big inch builds. With more cubic inches, those engines could actually use the extra flow.

The Twin Cams (1999–2016) carried on with 1 ¾″ stock head pipes, but Harley’s Screamin’ Eagle catalog and plenty of aftermarket builders began offering 1 ⅞″ and 2″ options. Many of those setups used stepped headers, which helped maintain low end torque while opening up top end power.

Today’s Milwaukee Eights (2017 and up) complicate things a bit. Stock head pipes are actually asymmetrical — one side usually around 1 ¾″, the other closer to 1 ⅞″. That’s partly for heat control and catalytic converter packaging. Performance systems often even things out, with both sides at 1 ⅞″ or even 2″, and stepped designs remain popular for balancing torque and horsepower.

Fitment tip: Matching header diameter to your muffler inlet or exhaust port is just the start. Watch your flange style, stud size, and O₂ bung location, or you’ll be chasing leaks and headaches. If you’re stepping into bigger primaries, stepped headers are a smart way to keep your torque curve happy without giving up top-end pull.

Sound Science and the Backpressure Myth

Baffles aren’t just there to keep your neighbors from calling the cops they’re an important part of how an exhaust system works. A good set of baffles helps control the timing and speed of exhaust pulses, which in turn affects how efficiently your engine breathes. Many riders throw around the phrase “you need backpressure” as if restriction is somehow good for performance. The truth is, engines don’t thrive on restriction they thrive on velocity.

What you actually want is smooth, consistent exhaust flow with properly timed pressure waves. When exhaust pulses leave the cylinder, they create a vacuum effect that helps pull the next charge of fresh air and fuel into the combustion chamber. This is called scavenging, and it’s the real key to power and throttle response not “backpressure” in the old school sense.

If your pipe is too wide or too short, those pulses slow down or bounce back at the wrong time, and scavenging suffers. The result? Flat spots, lazy throttle, and sometimes even backfiring. This is why simply cutting out baffles or running open drag pipes often makes a bike run worse, especially at low and mid RPMs.

Well designed baffles, tuned pipe length, and the right diameter work together to keep exhaust gas velocity high and pulses timed correctly. This is also why 2 into 1 systems are so often praised for performance they merge the flow from both cylinders in a way that sharpens scavenging and smooths the power curve.

So the takeaway is this: “backpressure” isn’t the goal—maintaining exhaust velocity and pulse timing is. That’s where your power, torque, and throttle response come from. And when you understand that, you start to see why some pipes sound great but run like a dog, while others might be quieter but absolutely wake the bike up.

Why You Can’t Trust Videos

This is where most riders mess up. The worst thing you can do is choose an exhaust based solely on a video. No matter how good the microphone is, it will never capture the full depth, tone, and presence of the real thing. A clip might give you a rough idea of the character, but it’ll never tell you how it feels in your chest when the bike fires up. If you want the truth, you’ve got to hear it in person. Go to bike nights, rallies, and dealership events. Walk the lot, listen to bikes as they roll in, and stand close enough to catch the real tone. Talk to riders—most will gladly give you a quick throttle blip. If you’re lucky, you might even swap a set of slip-ons with a buddy and take a short ride. And don’t be afraid to ask riders at gas stations, parking lots, or roadside pull offs if you see a setup you like—just be respectful, and you’ll almost always get a smile and

Material, Finish, and Heat Management

Pipes aren’t just pipes—they’re a mix of materials, coatings, and finishes that affect performance, looks, and comfort. Chrome will always have that timeless shine, but it shows bluing and scratches faster. Black ceramic coatings hold up better to heat and are easier to keep clean. Brushed stainless gives a raw, industrial vibe that develops a patina over time and resists corrosion well.

Then there’s titanium—popular in the sportbike world for its incredible weight savings, but not the best choice for a Harley exhaust. At the high, sustained temperatures Harleys produce, titanium can become brittle, especially around welds. It also expands and contracts differently than steel, which can stress mounting points and cause cracking over time. For most Harley applications, stainless steel remains the sweet spot—it’s strong, heattolerant, relatively light, and easy to repair or modify if needed.

Ceramic coatings on the inside of headers reduce radiant heat and protect finishes, making a noticeable difference in leg-burning traffic. Heat shields protect your skin, pants, and paint while keeping the pipe finish looking fresh. Header wrap can cut down on heat and give a gritty, race-inspired look, though it can trap moisture and accelerate corrosion if the bike is ridden in wet conditions.

The Tuning Connection

Changing your exhaust almost always means changing how your bike breathes, and that means tuning. If you’re running EFI, you’ll need a tuner to adjust your fuel maps. For carbureted bikes, you’ll be swapping jets and dialing in the mixture to match the new flow. And if you’re unsure about carb tuning, The Carb Code on ThrashMetalCycles.com breaks down CV, Mikuni, and S&S setups in plain language—worth a read before you start chasing gremlins.

Before you ever crack the box on a new exhaust, check for clearance issues with saddlebags, floorboards, or passenger pegs. On older Harleys, confirm the flange style and make sure your exhaust studs are in good shape. If you’re running EFI, verify the new pipe has the right O₂ bung size for your sensors.

Bringing It All Together

Finding the right exhaust for your Harley isn’t about chasing the loudest pipes or the flashiest tips—it’s about finding the perfect balance of performance, sound, style, and practicality for the way you ride. When you match the pipe to your riding style, choose materials that hold up in the real world, and make sure your engine is tuned to take advantage of the new flow, you’re building more than just a look—you’re building a machine that feels right every time you twist the throttle.

It’s easy to get caught up in hype, marketing, or that one bike you saw screaming past on the highway. But when you take the time to listen in person, research your options, and understand the science behind scavenging and sound, you stop rolling the dice and start making informed decisions. That’s when the exhaust stops being just a part and becomes a piece of your bike’s personality.

At the end of the day, the right exhaust will make you want to ride more. It’ll make you grin when you hit the starter, nod when you hear the tone echo off the walls, and feel like the bike under you is truly yours. That’s the point. Choose smart, tune right, and every ride will sound and feel exactly how you imagined.