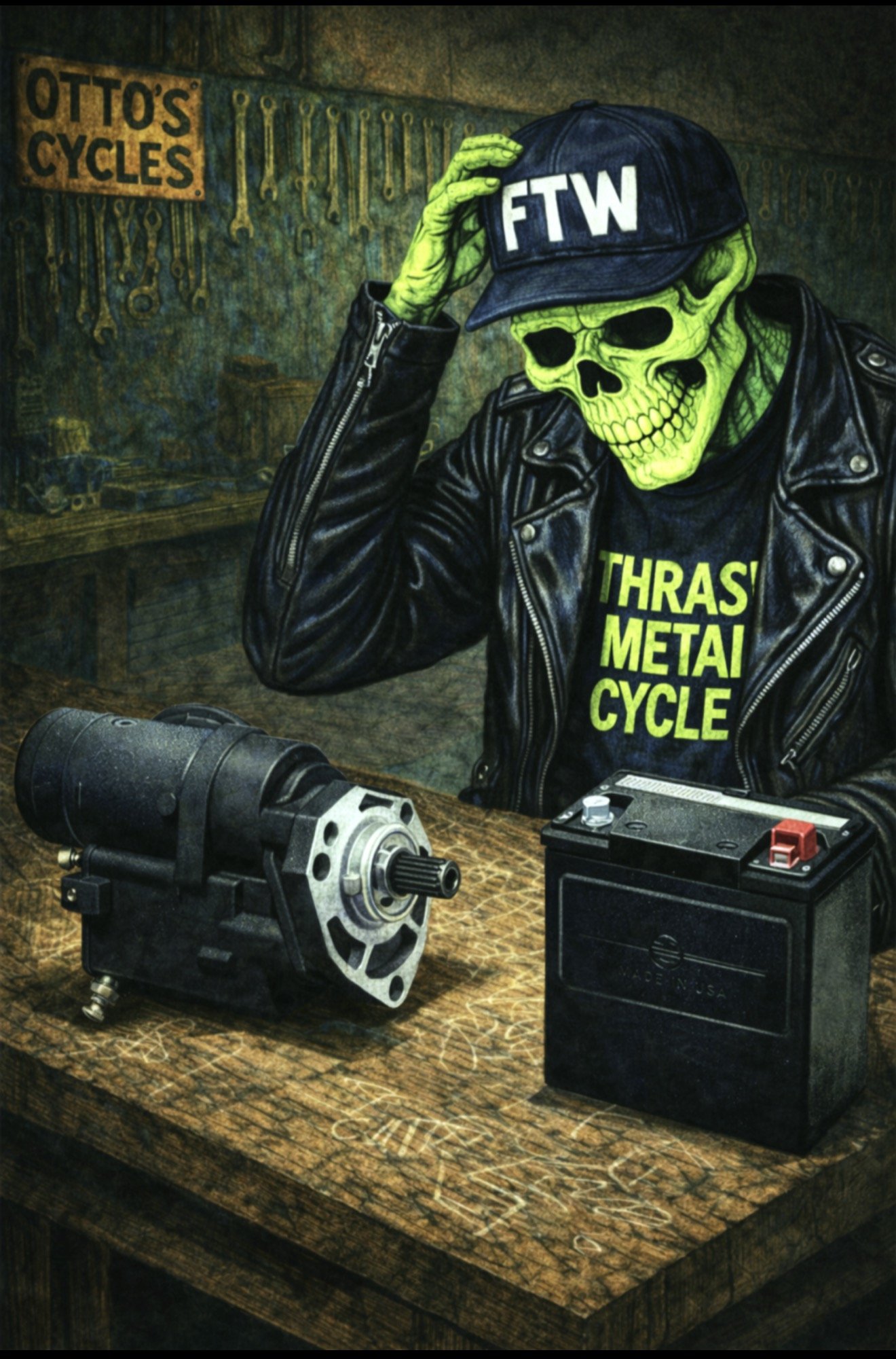

BATTERY & STARTER SYSTEMS: WHERE THE BEAST WAKES UP

Electricity is the breath of the beast. Without it, all that compression and chrome is just sculpture.

Everything starts with the battery. Not the starter, not the switch, not the button your thumb hits. The battery. It’s not just a box full of volts, it’s the pulse that feeds every spark, every light, every growl. When you hit the start button, that battery dumps more than 300 amps at 12 volts into the system. That’s a violent amount of current. That’s commitment.

Its job is simple. Feed everything. The starter motor. The solenoid. The ignition. The headlight. Injectors. Sensors. All the little gremlins hiding in modern wiring looms. If the battery is weak, everything starves. A tired battery doesn’t just crank slow, it drags your entire electrical world down with it. Keep it charged, clean, and mean.

The ignition switch is where the ritual begins. Turning the key doesn’t start the bike, it wakes it up. It turns stored energy into controlled fury. The switch doesn’t feed the starter directly, it couldn’t survive that load. It sends the command, not the muscle. When timing is marginal or voltage is low, this part of the circuit can help set the stage for starter kickback. That heart-stopping moment when the engine fights back. It’s not always timing. A lot of the time, it’s power starvation.

That little start button on the bars is just a whisper that starts a war. When you press it, you’re not sending power to the starter. You’re triggering the starter relay. The button itself only handles a trickle of current. The relay is the muscle that passes the surge down the line to the solenoid. Think of it like a preamp in a metal rig. Small signal, big noise.

Most stock Harley starter relays live somewhere in the 30 to 40 amp range. Fine for factory setups. Marginal once you start adding performance starters and higher compression. High-output solenoids can pull more than that just to slam the gear into the ring gear. The relay will still show voltage at the starter. It just won’t deliver the pressure. Voltage is potential. Amperage is force. No force, no fire.

When the relay sends the signal, the solenoid steps in like a metal god. It’s doing two jobs at once. It’s a high-current relay and a mechanical hammer. An electromagnet slams a plunger forward, closing the main contacts and physically driving the starter gear into the ring gear. That’s the moment your battery’s fury meets the flywheel. When those contacts kiss, everything commits.

Now the starter motor takes over, and this is where things get real. Starters can pull more than 300 amps just to roll the engine over. That’s not exaggeration. That’s physics. Performance engines need every volt they can get. Weak batteries, corroded cables, cheap connections, all of it is like trying to scream through a pillow. The motor is trying to work, but the system can’t feed it.

This is where a lot of bikes get sabotaged quietly, by their own cables. Everyone obsesses over the positive lead and forgets the return path. Electricity flows in a loop. If your ground cable is weak, corroded, or undersized, you’ve just cut your system’s legs out from under it. At 300 amps, every crimp matters. Every bolt matters. Every strand matters. Upgrade both cables. Heavy gauge. Clean ends. Solid grounds. No exceptions.

A healthy system tells the truth if you know where to look. A battery at rest should sit around 12.5 volts. While cranking, measured right at the battery terminals, it should never drop below 9.6 volts. If you see it fall under about 5.6 volts, you’re dealing with a bad cell. Jump-starting a shorted battery won’t save you. Disconnect it completely before trying another power source.

You also have to match the battery to the starter. A stock one kilowatt starter is happy with around 275 CCA. Step up to a 1.4 and you want at least 300. An 1.8 needs closer to 385. Big 2.4 kilowatt units want 500 CCA or more. A starter doesn’t create energy. It just converts it. If the battery can’t feed it, that big starter is just cooking itself alive.

One of the ugliest failures in the system is premature ignition firing, the kickback that makes your whole body flinch. That isn’t a ghost. It’s voltage drop. When voltage falls below an ignition module’s dropout threshold, depending on design, the coil shuts off. As the magnetic field collapses, it still throws a spark. If that spark happens before top dead center, the engine fires backward against the starter’s rotation. You hear it. You feel it. And your starter just took a hammer to the jaw.

Weak batteries, corroded wiring, dirty ignition switch contacts, all of it can cause that moment. Every voltage dip is flirting with destruction. Feed your ignition clean, uninterrupted power and most of that violence disappears.

Electricity isn’t magic. It’s loyalty. Treat it right and it gives you life. Ignore it and it burns starters, melts wires, and kicks motors in the teeth. Clean grounds. Heavy cables. A battery that bites back. Every ride begins with a spark. Make sure yours lights the fuse, not the fire.

Thrash Metal Cycles.

Fuel. Fire. Fury. And 12.5 volts of pure defiance.

If you want next passes, we can:

• Make a spoken-word version for video narration

• Strip this into a short-form IG carousel

• Or flow it directly into a Charging System follow-up so this becomes Chapter One