A Harly Davidson ignition reality check

By Thrash Metal Cycle

Here We Go…

Before You Blame the Carb, Test the Spark

Herman, Struggles To Figure Out the Process

If your Harley is acting weird, you do not start by blaming the carb like it insulted your mother.

You start by proving the spark system has the juice to do its job. Weak ignition does not always die with fireworks. Sometimes it just gets lazy. Sometimes it lies only when the motor is hot. Sometimes it looks fine in open air and folds under cylinder pressure like a cheap lawn chair.

Herman has learned this the expensive way. So you do the simple checks first, the ones that stop you from throwing parts into the void.

Start at the battery. Always.

Ignition systems do not run on confidence. They run on voltage. Set your meter to DC volts. Put the red lead on battery positive and the black lead on battery negative.

Bike off, you are looking for a healthy resting number. A fully charged battery sits around 12.8 volts. Around 12.6 volts is roughly three quarters charged, and you are already sliding toward trouble if the bike is picky about cold starts.

Now the part people skip because it ruins their favorite theory and everyone, it seems, has a theory. Put the meter where you can see it and crank the bike. If the voltage collapses under load, your ignition is fighting with one hand tied behind its back.

When you load test a 12-volt battery the old-school way, the industry rule is simple. Pull it at half its cold cranking amps for fifteen seconds. At seventy degrees’ish is good enough, it needs to hold at least 9.6 volts. If it drops below that, the battery doesn’t have the guts to support an ignition under load. That isn’t a Harley opinion. That’s how batteries get judged everywhere.

Key on. Run stop switch set to run. Now do not just chase continuity like it is the holy grail. What you care about is whether the circuit delivers voltage under real conditions. A quick truth test is checking for voltage at the point you are feeding, and it should be within about one volt of battery voltage. If it is not, the circuit is dropping voltage somewhere before it gets to the ignition, and that can mimic carb problems all day.

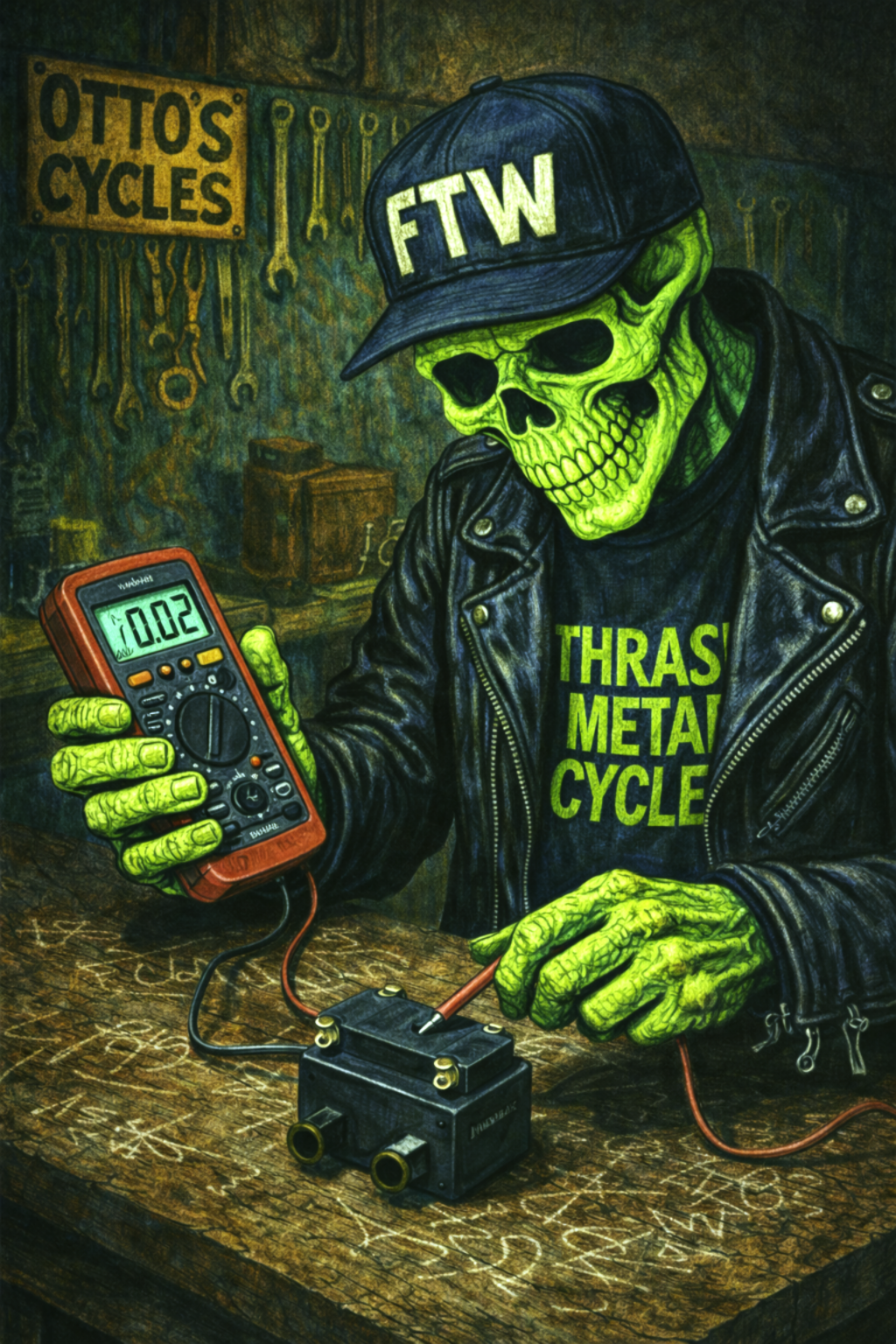

Where DO You Even Prob A Coil? Herman Still Struggles.

If you want to get serious without getting fancy, do a voltage drop test. When the circuit is active, measure from the source to the load. The book rule is simple. If you see a drop of one volt or more, that is excessive resistance in the circuit. Translation. Corrosion, loose pins, cooked contacts, broken wire inside the insulation, the usual haunted house stuff.

Now we talk coil, but we talk coil the right way.

Ignition off. Disconnect the coil so you are measuring the coil, not the whole motorcycle. Set the meter to ohms.

Primary resistance is measured across the small primary terminals. Secondary resistance is measured between the high tension towers where the plug wires connect, or on some coils, between the specified secondary points in the manual.

Here is the part where the internet gets people hurt. There is no single “Harley coil should be 3 ohms” rule that applies across 1970 to 2005. Harley changed systems. Aftermarket changed coils. Dual fire and single fire coils have different designs. EFI era coils can spec very different than points era coils. If you print one number like it is gospel, somebody will swear their good coil is bad, or worse, they will run the wrong coil and cook a module.

If we are talking points era big twin, the FL and FX manual spells it out. Primary 4.7 to 5.7 ohms. Secondary 16,000 to 20,000 ohms.

If we are talking a later model example from the 2000 to 2005 Softail book, one of the listed ignition coil specs is primary 0.5 to 0.7 ohms and secondary 5,500 to 7,500 ohms.

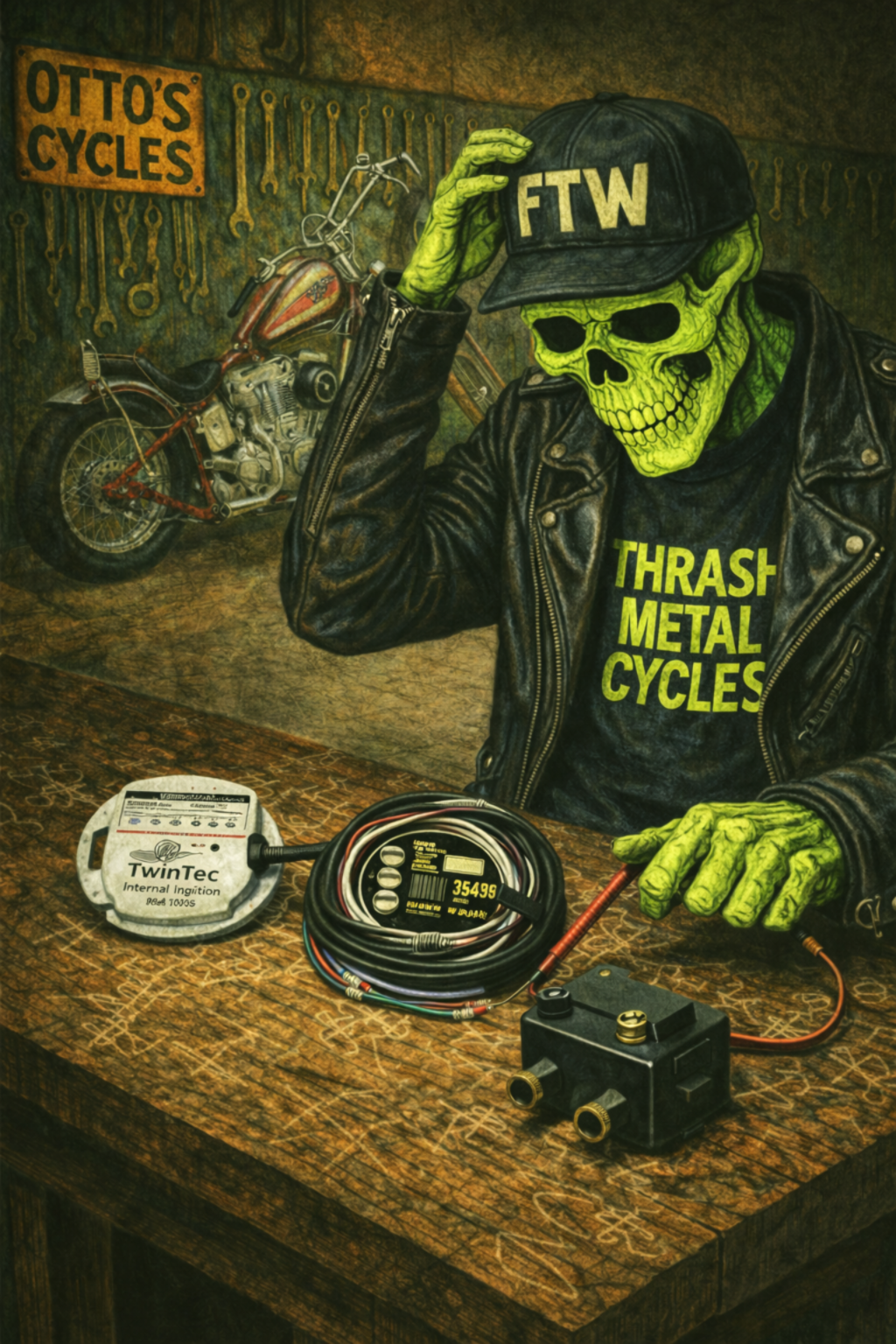

Choices…

That spread right there is why the line, “most Harleys are three ohm electronic and five ohm points” line needs to go. It is not that the vibe is wrong. It’s that a confident wrong number is more dangerous than no number at all.

So here is the way we say it in TMC language.

You measure primary and secondary resistance and you compare it to the service manual spec for that bike and that ignition setup. If you do not have the exact spec, you do not declare it good just because it landed somewhere that feels familiar. You treat it like a lead, not a verdict.

Also test it cold and then test it hot. The 2000 to 2005 Softail book literally tells you to test the coil twice, room temperature and then normal operating temperature. If the engine will not start, heat the coil with a hair dryer and test again. Heat related failures are real.

After the resistance checks, do not ignore the plug wires and caps. On resistor type cables, damage increases resistance and causes misfire and driveability issues. If the wire is cracked, arcing, corroded at the ends, or the boots are split, you fix that before you crown the coil guilty.

If your numbers are out of spec, replace the coil. If the numbers are close but you see corrosion at the terminals, clean them and retest. The book calls out that high readings can be corrosion or oxidation at the terminals, and if cleaning does not bring it back, the coil is done.

That is the whole point of this article.

You are not worshipping the meter. You are using it to stop guessing.

Prove the battery. Prove the power path. Prove the coil against the correct spec for that system. Then and only then do you go chasing carbs, timing, sensors, and fuel like a maniac.

Harleys do not punish wrenching. They punish guesswork.

Grab the meter. Herman is not letting you buy parts until you earn it.